Feb 23 2023

Worked backwards from a desired distance making the following assumptions:

We want the torpedo to travel 0.5m or about 20” 0.2m or about 8”

Torpedo mass of 10g

Compression of the spring by 1 cm or 0.01m

Damping/drag coefficient of 0.1

Calculations redone in next table

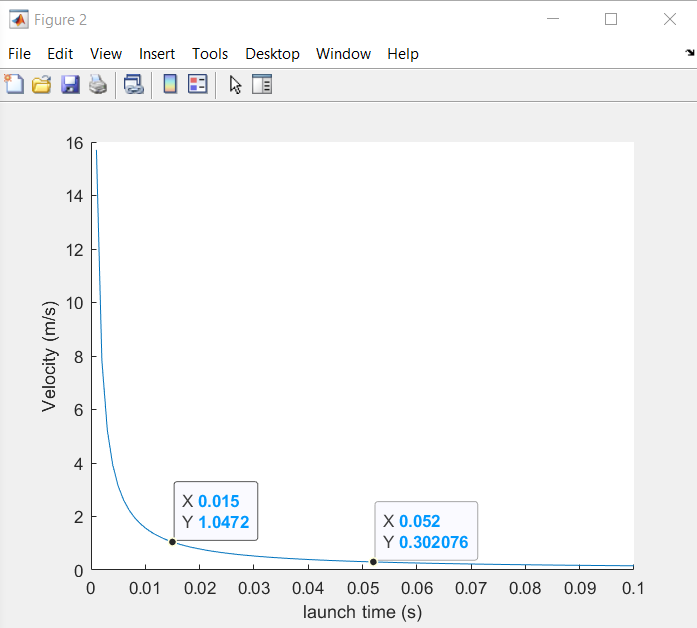

Worked backwards from the speed of the torpedo after launch to find desired speed

|

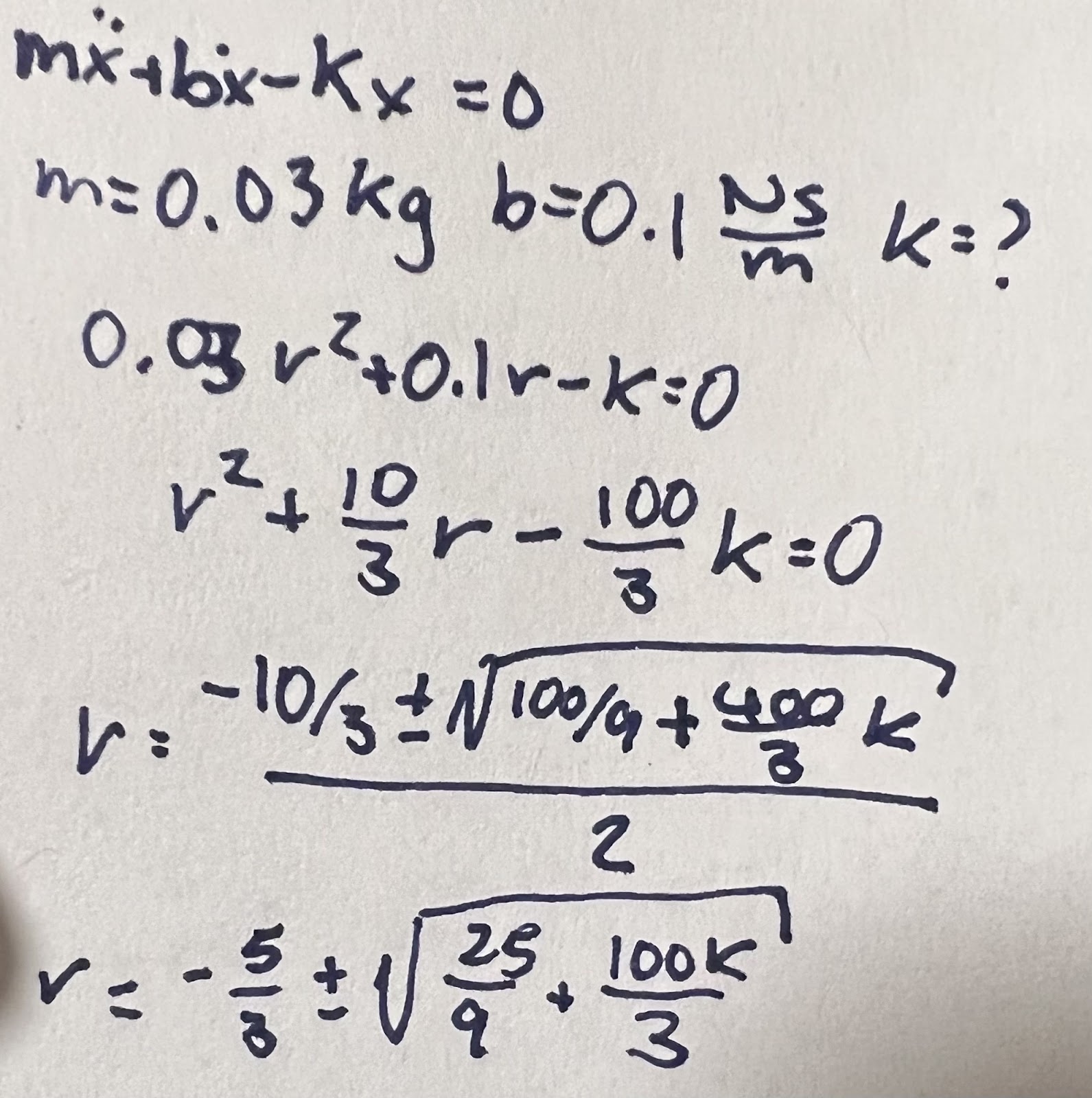

Wrote out ODE of the spring in launching action |

|

|

Did not solve on my calculator as the notes suggest—was giving a domain error. Instead, I solved the system on MATLAB to find the minimum spring constant with the desired velocity. |

% Lindsay Wright

% RoboSubSpring.m

% State Space for Spring and Water Damping

% Last Modified: 2/23/23

%Some assumptions: a drag coefficient of 0.01 Ns/m, pushback of 1 cm at the

%start

t=0.001:0.001:0.1;

kPlot=zeros(1,length(0.005:0.005:0.5));

vPlot=zeros(1,length(0.005:0.005:0.5));

for i=1:length(t)

kPlot(i)=((pi/2/t(i))^2+25)/100;

vPlot(i)=(pi/2)*0.01/t(i)*exp(-5*t(i));

end

figure

plot(t,kPlot)

xlabel('launch time (s)')

ylabel('Spring Constant (N/m)')

figure

plot(t,vPlot)

xlabel('launch time (s)')

ylabel('Velocity (m/s)')

table=zeros(3,length(t));

table(1,:)=t;

table(2,:)=kPlot;

table(3,:)=vPlot;

disp(table) |

Conclusion: Need a minimum spring constant of 2750 N/m That is a powerful spring! |

Changing the distance requirement to 0.2m (about 8”) makes the needed initial velocity 2 m/s

This yields a spring constant of ~500 N/m

|

Changing the distance requirement to 0.3m (about 1’) makes the needed initial velocity 3 m/s

This yields a spring constant of ~1000 N/m or ~560 lbs/in |

close all; clear; clc;

% Lindsay Wright

% RoboSubSpring.m

% State Space for Spring and Water Damping

% Last Modified: 2/25/23

%Some assumptions: a drag coefficient of 0.01 Ns/m, pushback of 1 cm at the

%start

t=0.001:0.001:0.1;

kPlot=zeros(1,length(0.005:0.005:0.5));

vPlot=zeros(1,length(0.005:0.005:0.5));

for i=1:length(t)

kPlot(i)=((pi/2/t(i))^2+25)/100;

vPlot(i)=(pi/2)*0.03/t(i)*exp(-5*t(i)); %changed 0.01 kg to 0.03 kg

end

desired_travel = 5; % in meters

diff_val = abs(desired_travel*ones(1,length(t))-vPlot);

index = find(min(diff_val) == diff_val);

%index = find(vPlot == );

figure

hold on

plot(t,kPlot)

plot(t(index),kPlot(index),'LineStyle', 'none','Marker','o','MarkerSize',5,'MarkerFaceColor','red','MarkerEdgeColor','none')

hold off

xlabel('launch time (s)')

ylabel('Spring Constant (N/m)')

figure

hold on

plot(t,vPlot)

plot(t(index),vPlot(index),'LineStyle', 'none','Marker','o','MarkerSize',5,'MarkerFaceColor','red','MarkerEdgeColor','none')

hold off

xlabel('launch time (s)')

ylabel('Velocity (m/s)')

table=zeros(3,length(t));

table(1,:)=t;

table(2,:)=kPlot;

table(3,:)=vPlot;

%disp(table)

fprintf('need: %07.4f N/m or %08.4f lb/in to travel: %07.4f meters\n',kPlot(index),kPlot(index)*8.8507457676,vPlot(index))

20230301

Calculations redone to account for differences in mass. Also realized I made an error in calculating the roots of the characteristic equation, yielding a smaller spring constant than expected.

|

|

|

|

% Lindsay Wright

% RoboSubSpring.m

% State Space for Spring and Water Damping

% Last Modified: 3/1/23

%Some assumptions: a drag coefficient of 0.01 Ns/m, pushback of 1 cm at the

%start

t=0.001:0.001:0.1;

kPlot=zeros(1,length(0.005:0.005:0.5));

vPlot=zeros(1,length(0.005:0.005:0.5));

for i=1:length(t)

kPlot(i)=((pi/2/t(i))^2+25/9)*3/100;

vPlot(i)=(pi/2)*0.01/t(i); %changed 0.01 kg to 0.03 kg

end

desired_travel = 0.3; % in meters

diff_val = abs(desired_travel*ones(1,length(t))-vPlot);

index = find(min(diff_val) == diff_val);

%index = find(vPlot == );

figure

hold on

plot(t,kPlot)

plot(t(index),kPlot(index),'LineStyle', 'none','Marker','o','MarkerSize',5,'MarkerFaceColor','red','MarkerEdgeColor','none')

hold off

xlabel('launch time (s)')

ylabel('Spring Constant (N/m)')

figure

hold on

plot(t,vPlot)

plot(t(index),vPlot(index),'LineStyle', 'none','Marker','o','MarkerSize',5,'MarkerFaceColor','red','MarkerEdgeColor','none')

hold off

xlabel('launch time (s)')

ylabel('Velocity (m/s)')

table=zeros(3,length(t));

table(1,:)=t;

table(2,:)=kPlot;

table(3,:)=vPlot;

%disp(table)

fprintf('need: %07.4f N/m or %08.4f lb/in to travel: %07.4f meters\n',kPlot(index),kPlot(index)*8.8507457676,vPlot(index)) |

Or, ~1.89 lb/in |